Permitting and Code

for Graywater Systems

Obey the law

Design safe and healthy systems. Educate yourself as to how to follow code guidelines for permit-exempt systems and obtain necessary permits where required.

Concerns of Regulators

Contamination of potable water

Backflow prevention and/or air gap

Runoff

Litigation,

odor complaints

Graywater entering storm drains is Illegal and causes watershed pollution

Pooling, ponding

Mosquitoes, exposure

Piping infrastructure

Ratio of liquids to solids to keep wastewater moving

Code Compliance?

Historical low code compliance rates in California (<1%)

People deterred by perception of impractical code requirements

Few professionals installing graywater systems

Development of graywater code in recent years facilitates professional installation

Opportunity for landscape and plumbing industries

The 3 Types of Graywater Systems as Defined by CA Code

Clothes Washer System (1602.1.1)

Doesn't alter drainage plumbing

Follows 12 guidelines

Doesn’t need permit

Simple System (1602.1.2)

Up to 250 gallons/day or less

Any amount of fixtures

Needs permit

Complex System (1602.1.3)

Over 250 gallons/day, any amount of fixtures, designed by a person who demonstrates competence, needs permit

Clothes Washer System Guidelines

( Permit exempt if no alteration to existing plumbing and system follows 12 code guidelines)

Notification of installation of the system to Enforcing Agency (county or city permitting department, environmental health, public works, etc)

User can easily redirect flow to sewer

No potable water connection

The graywater shall be contained on the site where it is generated

Graywater shall be directed to and contained within an irrigation or disposal field

Ponding or runoff is prohibited and shall be considered a nuisance

At least two (2) inches of mulch, rock, soil, or a solid shield covers the release point

Minimize contact with humans and domestic pets.

Water used for diaper washing and similarly soiled or infectious garments shall be diverted to the building sewer.

Graywater shall not contain hazardous chemicals derived from activities such as cleaning car parts, washing greasy or oily rags, or disposing of waste solutions from home photo labs or similar hobbyist or home occupational activities.

Exemption from construction permit requirements of this code shall not be deemed to grant authorization for any gray water system to be installed in a manner that violates other provisions of this code or any other laws or ordinances of the enforcing agency.

An operation and maintenance manual shall be provided.

Setbacks for Outlets

Follow required setbacks for a code-compliant system.

Key points

from the Graywater Code

Discharge (1602.2.1)

To a subsurface/subsoil irrigation system/disposal field

Residential occupancies can discharge to a mulch basin

Surge Capacity (1602.2.2)

Designed system must accommodate peak flow rates and discharge all water on a daily basis

A surge tank is required for systems that can’t discharge the total amount by gravity drainage

Diversion (1602.2.3)

Must occur downstream of traps and vent connections

The diverter valve must be readily accessible and indicate flow direction

Backwater Valves (1602.2.4)

Install at the point of connection to the building sewer system for locations that are subject to backflow

Permitting Requirements

Check with the jurisdiction in which the graywater system is being installed.

Drawings and Specifications(1602.7)

Plot plan details

Holding tank details

Soil absorption qualities from percolation test

Site Surface water locations

Operations and Maintenance Manual (1601.6)

Diagrams of the system and location of components.

How and when to turn the system off and on.

Appropriate products to use

Any maintenance needed

Contact info for the installer and/or manufacturer

Pictures and other documentation of the piping before it is buried

Licensed professional for complex systems (1601.2)

“Complex Systems” are defined as those producing over 250 gallons/day, from any amount of fixtures.

Design may require a licensed professional.

• Civil Engineer

Plot Plan

(to scale)

Lot lines / slope

Retaining walls / drainage channels / paved areas / structures

Water supply lines / plumbing fixtures

Water and sewer system (private and/or public)

Location of proposed gray water system

Soil / groundwater

Absence of groundwater can be proven by digging a 3 ft. test hole (ideally below the depth of the mulch basin)

Conduct a soil test and contact local enforcement agency for requirements

Backflow Prevention Device

Systems that use a pump or that have a potable water connection will require a Backflow prevention devices (BFPD) which ensures water quality by preventing contamination of the potable (drinking) water supply due to back-pressure or back-siphonage of graywater into the municipal system. Local regulations vary as to acceptable backflow standards but generally speaking the Reduced pressure (RP) backflow device ( RP valve) is the most reliable backflow prevention device and can protect against both back- pressure and back-siphonage. Above ground installation is required with concrete stabilization and a minimum 12-inch gap between the relief valve and finished grade to allow the RP to discharge water when a back-siphon situation occurs. Backflow preventer devices are legally required to be inspected annually by a certified backflow inspector.

Diversion downstream from Traps & Vents

Vent pipes provide an outlet and inlet for this air and prevent a vacuum from being formed that could suck the water out of the p-trap (which is meant to stay full all the time). In order for the vent to work though it must be downstream and within a certain distance from the P-trap, known as the “critical distance”. Vent pipes are easy to confuse as drain lines when one is unfamiliar with plumbing. 3-way diverter valves should always be located downstream of P-traps & Vents, otherwise they would cut off their essential function.

Operation and Maintenance Manual

Required info:

Diagram(s) of the system and location of components

Instructions on operating the system

Details on start-up, shut-down, and deactivation

Applicable testing, inspection and maintenance

Contact info of installer/designer and component manufacturer

Directions that the O&M manual needs to remain with the building for the life of the structure

Other helpful info:

What kinds of soaps to use

A picture of the tubing before it is buried

Labeling Requirements

To avoid future confusion Graywater distribution piping has to be labeled to identify it as being Non-potable water. The words “CAUTION: NONPOTABLE GRAY WATER, DO NOT DRINK” should be marked on the pipe at intervals not to exceed every 5 ft.

The 3-way diverter valve in the indoor assembly of the Laundry-to-Landscape System is also required to be labeled as to which handle direction sends the graywater to sewer or landscape.

Sizing Drainpipes

Drain line pipes are sized according to the number of “drainage fixture units” they carry. Each type of fixture (ie. shower, sink, toilet) has a different number of “units” assigned to it in the plumbing code.

Maximum Unit Loading

Add up all the units of the fixtures you want to connect to determine what size pipe is necessary. Whether the section of pipe is vertical or horizontal also determines the amount of units it can carry. The vast majority of single family home graywater systems will be fine with a 2” pipe, and only the largest systems will need a bigger size pipe.

For example, a typical branched drain system may include a shower(2 units), a sink (1 unit), a bathtub(2) and a laundry (3) for a total of 8 units, which still fits in a 2” pipe but is the maximum units allowed in that pipe size.

Estimating Graywater Production

Using the Code formula (1602.8.1) requires knowing the number of bedrooms in the house, which determines the number of theoretical occupants:

1st bedroom = 2 occupants

Additional bedrooms = 1 occupant

Add up the total occupants and then multiply the total number of occupants by the estimated graywater production per-occupant accordingly:

Laundry = 15 GPD (gallons per day) per occupant

Showers, bathtubs, and wash basins = 25 GPD per occupant

See the example at right for a complete calculation process for a four bedroom house.

Sizing Infiltration Areas

The area (square feet) of mulch basins needed is determined by dividing the estimated number of gallons produced per day by the soil type’s maximum absorption capacity (measured in gallons/sq2). Use Code Table 1602.10 at right for common soil types. See examples below for complete calculation for 2 different soil types with an estimated daily graywater production of 125 gpd.

Coarse sand or gravel: 125 gal/day / 5 gal/ft2/day = 25 ft2

Clay w/small amounts of sand or gravel: 125 gal/day / 0.8 gal/ft2/day = 156.25 ft2

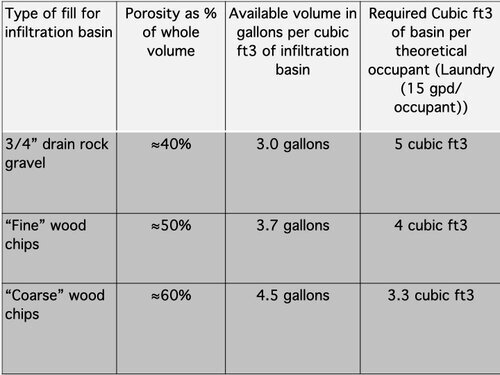

Surge Capacity

The open pore space between the particles of wood chips, gravel drain rock, or other chunky organic material in the infiltration basins provides open space in which the surge of graywater fills preventing it from being exposed to the surface (which is prohibited). Approximately 40-60% of the volume in an infiltration basin is occupied by the refill material depending on the exact type used. By calculating the total volume of the excavation and subtracting the volume occupied by the fill material we can get a rough idea of the available surge capacity in Cubic feet and then convert that to gallons (There are 7.48 gallons in a cubic ft3).

(Gallons of estimated graywater discharge per day / 7.48) / porosity (expressed as a decimal) = Cubic ft3 of infiltration basin required

Ensure the available volume of the infiltration basin exceeds the calculated surge volume of the daily greywater production.